product center

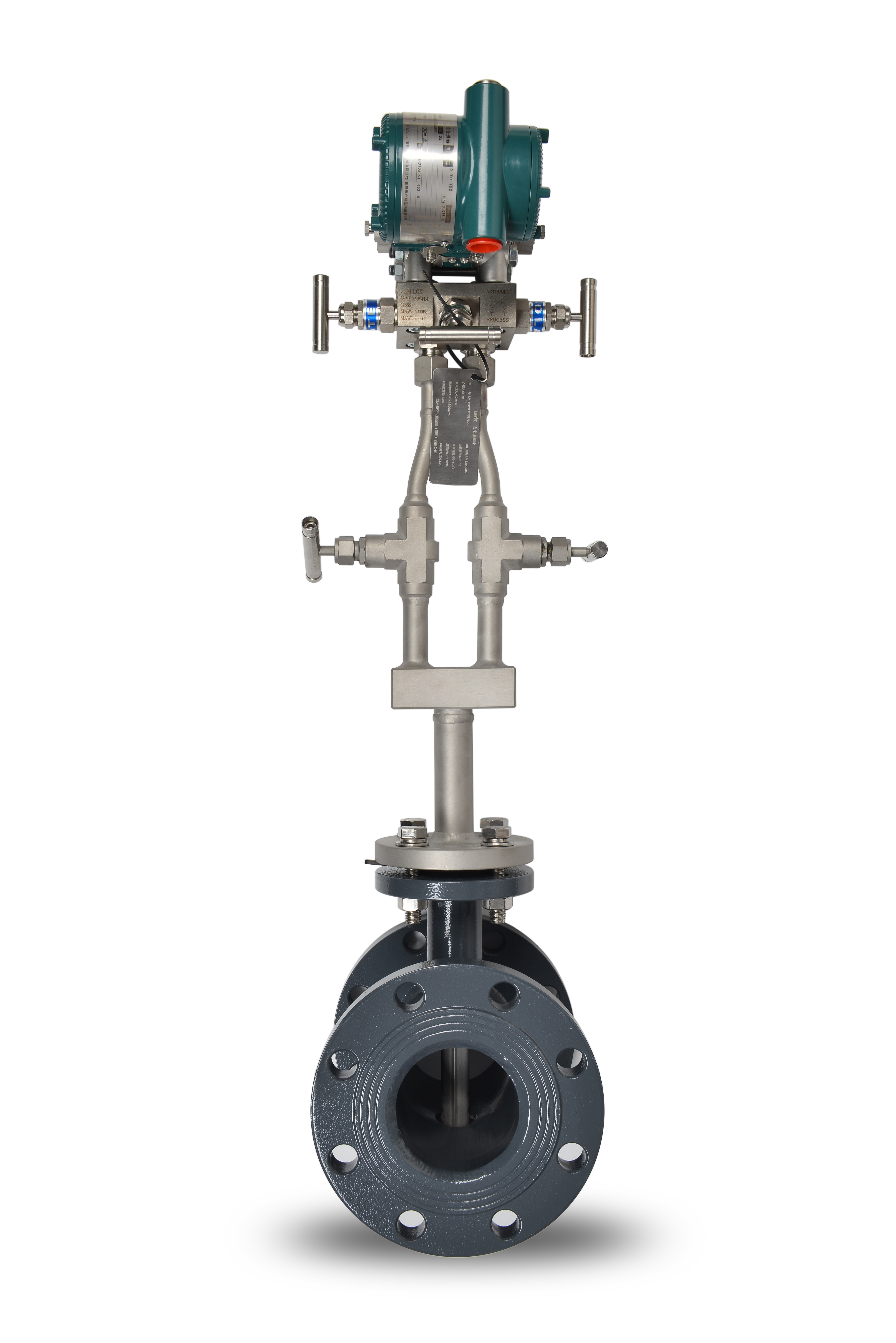

A new type of plug-in flow measurement instrument designed and produced based on the principle of differential pressure, consisting of a flow sensor, differential pressure transmitter, and flow integrator (or quantity controller, DCS), etc

technical parameter

Accuracy: 1% (R)

Repeatability: 0.1%

Accuracy: 1.0, 1.5

Range ratio: 30:1, bidirectional measurement

Pipe diameter: 3mm~15m

Temperature range:- 200℃~550℃

Pressure range:- 0.03MPa~25MPa

Measurement media: gases, liquids, vapors, and corrosive media, etc

Installation method

Integrated installation method and split installation method

Installation characteristics of different media

Gas medium

l When measuring gas, the differential pressure signal is transmitted to the differential pressure transmitter through the gas, so attention should be paid to the impact of condensed water.

l When installing differential pressure transmitters, efforts should be made to avoid the measurement impact caused by condensed water.

l When installing, try to insert from top to bottom to achieve better measurement results.

l Whether it is an integrated or split installation, the position of the three valve group and differential pressure transmitter must be higher than the probe differential pressure output port, otherwise it will affect the measurement.

Ø Gas measurement installation method: Installation at the top of a horizontal pipeline

Liquid medium

lWhen measuring liquids, the differential pressure signal is transmitted through the liquid to the differential pressure transmitter. If there are bubbles in the liquid, it will cause measurement errors.

lWhen installing differential pressure transmitters, efforts should be made to avoid the generation of bubbles.

lWhen installing, try to insert from bottom to top to achieve better measurement results.

lWhether it is an integrated or split installation, the position of the three valve group and differential pressure transmitter must be lower than the probe differential pressure output port, otherwise it will affect the measurement effect.

Ø Installation method for measuring liquids: installation at the bottom of a horizontal pipeline

Ø Installation method for measuring liquids: vertical pipeline and horizontal installation

Steam medium

lWhen measuring steam, both integrated and separated flow sensors are equipped with micro condensers, and the differential pressure signal is transmitted to the differential pressure transmitter through the condensed water.

lWhether it is a horizontal or vertical pipeline, the probe for measuring steam is always inserted horizontally (except in special circumstances).

lWhen installing, make sure to keep the left and right condensers in a horizontal position.

lWhether it is an integrated or split installation, the position of the three valve group and differential pressure transmitter must be lower than the probe differential pressure output port, otherwise measurement will not be possible.

Ø Steam measurement installation method: horizontal pipeline installation

Ø Steam measurement installation method: vertical pipeline installation